Oloa

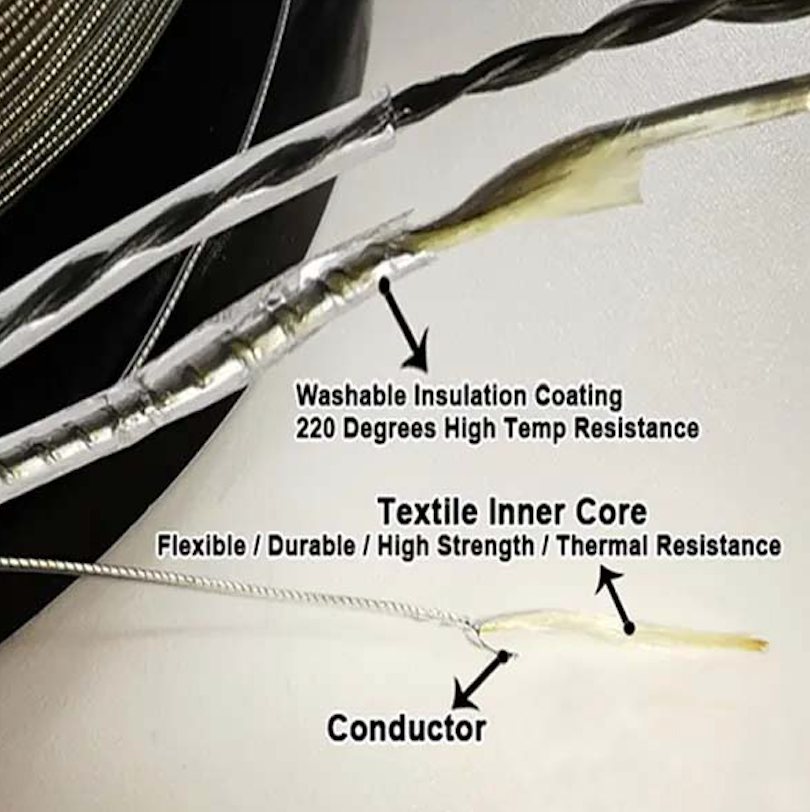

Alava fusi uamea leila po'o le ie i totonu autu conductive uaea mo ie vevela

Fa'amatalaga o oloa

1-Alava uamea e fa'avae fusi fa'avae lea o le lautele o alava ta'itasi e 12µ po'o 14µ. Ole aofa'i ole alava e masani lava ile 200 ile sili atu ile 1500 filaments. O lenei mea e te maua ai se umi e sili ona lelei i le vasega'. Ona o alava lelei o loʻo faʻaaogaina, o nei uaea o loʻo tumau pea le manifinifi i le lautele lautele ma faʻapea e matua fetuutuunai i le gaosiga.

2-Matou te ufiufi le lautele lautele o le maualalo o le teteʻe faʻaopoopo uaea lelei ma micro cables ma uiga umi ma fetuutuunai, faʻapitoa a matou ie i totonu totonu micro cables e mafai ona faʻamaonia le teteʻe i le mita e te manaʻomia ma tuʻuina atu ia te oe le sili atu ona fetuutuunai i le mamanu ae o loʻo ofoina atu pea se sili atu. flex-ola nai lo masani Cu-uaea. Faʻalagolago i le faʻapipiʻi pito i fafo e mafai ona tuʻuina, apamemea, uʻamea siliva ma isi, e mafai ona tatou gaosia le faʻamalosi e oʻo lava i lalo ifo o le 1 ohm / m micro cables e tasi ma paʻia ituaiga e tusa ai ma manaoga o tagata faatau.

Ie i totonu totonu micro cables lelei

Fa'asagaga Pi'o

Ona o le fausaga ma le tuʻufaʻatasia o meafaitino, o le uaea e sili ona lelei le teteʻe.

Fetuuna'i

Ole micro cables e fa'aogaina le pepa u'amea manifinifi e fai ma ta'ita'i, e iloa ai le fetuutuuna'i sili.

Matua-Fine

Ina ua uma extrusion tatou micro cable thinest e mafai ona 0.35mm.

Malosi maualuga

Matou te fa'aogaina alava Aramid / Liquid Crystal Polymer ma fa'ainisinia a latou lava alava tekonolosi maualuga.

Maualuluga Temp. Tete'e

Matou te faʻaaogaina filaments faʻapipiʻi faʻapipiʻi aramid poʻo stanless fiber mo alava, maualuga le vevela mai le 230 tikeri i le 580 tikeri mo lau filifiliga.

Fa'auma & fa'alavalava

I lau lalolagi, e tele lava ina mana'omia mo le lacquering ta'ito'atasi o filaments po'o se fa'apipi'i fa'ato'a atoa i luga o le uaea atoa. E mafai foʻi ona tatou faia lena mea, o a tatou mea faʻapipiʻi e aofia ai FEP, PFA, PTFE, TPU ma isi.

FA'AMATALAGA O LE EPA INSULATION

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205°C | 255°C | 250°C |

| Cgalue faifai pea Temperature | 165°C | 205°C | 225°C |

Fa'aigoa Fiber Uamea

Ie Inner Core Micro Cable Fausia

Fa'avae Embroided Heating Element

Uamea uamea fa'apipi'i laina fa'asaga eseese mo lau fa'amatalaga.

| Diamita (um) | Filaments | Malosi (cN) | mamafa (g/m) | Fa'aumi (%) | Amioga (Ohm/m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Textile totonu autu conductive uaea eseese tulaga tetee

| Fa'atonu i fafo | Ie I totonu Autu | Ole mita mm | Conductivity ≤Ω/m |

| Kopa 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| Kopa 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |

| Kopa 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Kopa 0.1mm | 200D Dinima | 0.22±0.02 | 4.00 |

| Kopa 0.1mm | 250D Polyester | 1*2/0.28 | 2.00 |

| Kopa 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| Kopa 0.05mm | 50D Polyester | 1*2/0.13 | 8.50 |

| Kopa 0.05mm | 70D Polyester | 0.11±0.02 | 12.50 |

| Kopa 0.55mm | 70D Polyester | 0.12±0.02 | 12.30 |

| Kopa 0.10mm | Cotton 42S/2 | 0.27±0.03 | 4.20 |

| Kopa 0.09mm | 150D Polyester | 0.19±0.02 | 5.50 |

| Kopa 0.06mm | 150D Polyester | 0.19±0.02 | 12.50 |

| Apa Apa 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Apa Apa 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| Apa Apa 0.06mm | 130D Kevlar | 0.16±0.02 | 12.50 |

| Apa Apa 0.10mm | 250D Polyester | 0.23±0.02 | 4.00 |

| Apa Apa 0.06mm | 150D Polyester | 0.16±0.02 | 11.6 |

| Apa Apa 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Apa Apa 0.085mm | 150D Polyester | 0.19±0.02 | 6.00 |

| Kopa Siliva 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |